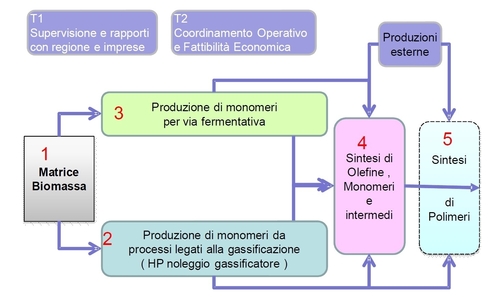

The GLV project involves the construction of a BIOMASS HUB, that of a "pilot plant" for the first experimental activities for the production of organic chemicals that can then be used from some companies interested in entering or strengthening their presence in the different phases of the Biomass / Bioplastics industry. In GLVP project is focused on the identification of all technical aspects related to the fundamental scientific activities, technological processes and a much stronger emphasis is applied on the evaluation of the economic and organizational system. Project Green Valley Lab has the aim to create a shareholding to ensure both the initial stage and the subsequent consolidation. The new production facilities, designed to operate in areas with a great potential for future growth, would be furthered by the synergies that may arise from locating in a Chemical industrial district, which is still among the best and safest in Europe (CUP: F72I15000590002)

Projects

Green Lab Valley

LIFE12/ENV/IT/00600

'Bio-inspired thermo / UV curable monomers and polymers' (BiMoP)

European project LIFE12 ENV / IT / 00600

Background:

Use of biomass based on starch waste from the food industry for the production of biodegradable and compostable chemical compounds.

Applications with monomers and polymers obtained from renewable resources as alternatives to chemical compounds dangerous for human health and the environment derived from fossil resources.

Main target:

Use of itaconic acid and its derivatives as raw materials for the production of biodegradable and compostable bioplasts

Main actions:

1.Production of biodegradable and compostable paints and adhesives for food packaging

2. Elimination of hazardous gases, such as formaldehyde and styrene contained into the unsaturated polyester and phenolic resins.

Project FIT L46/82 - A01/2233/00/X16

b

The main purpose of the program is the development of new polymer blends and the creation of a novel polymer materilas to be used as a raw material in the process known as "rotational molding" for applications in agricoltue as vessels. Compared to those currently used in rotational molding, the new polymer material is composed of mixtures containing polystyrene, plasticizers and thermoplastic elastomers, suitable for this type of process, so that it has high melt flowability, good dimensional stability with temperature, such as paintability and bonding, required in the chosen application in the selected field.

Green Cluster

In recent years, the demand for biodegradable and compostable polymer materials increases, i.e. they are able to be biodegraded by bacteria present in soil or water. In particular, this is a very important condition for use in landfills for recyclable USW (i.e. Urban Solid Waste), as it allows to significantly reduce volumes of polymer materials. These types of polymers can be added to organic waste recycling containers (wet fraction in USW). The compostability of biodegradable polymer materials is governed by the European Standard EN ISO 13432, which allows the Packaging Certification to be applied to polymeric packaging materials, which is usually provided by the Italian Composting Consortium (CIC), which releases the COMPOSTABLE logo as CIC.

Networks based on polymer materials are widely used as fruit and vegetable packagings. In fact, polymer nets are widely used for packaging potatoes, onions and fruits with special machines. The CIC label can be applied on heat sealed biodegradable film extruded with a conventional technology by cast film processing. There is usually a wide range of colors available. Two types of nets can be chosen, depending on the product: the woven mesh fabric ensures a good coverage of the sacked product and the best result in terms of gloss and color of the packaging. Instead, the nets with square mesh, thanks to its wider meshes, allows you to better show the content of the product and highlight its qualitative features.

The purpose of this project is to use industrial polymer materials derived from renewable resources, such as Polylactic acid (PLA) or mixtures of biodegradable polymers, such as modified starch (MS), polycaprolactone (PCL), polyhydroxyalkanoates (PHA) and polybutylensuccinates (PBS) for the production of biodegradable and compostable mono- and bi-oriented and tubular for food packaging applications as per EN ISO 13432/2002 (CUP: E72C10000140001).