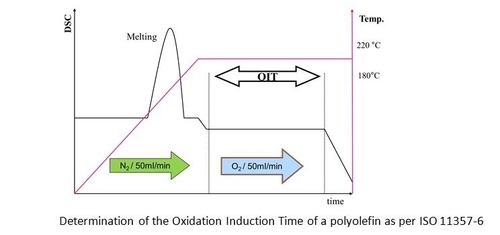

Scanning Calorimeter (DSC) Analysis for the Determination of the Effectiveness of Antioxidants is generally contained in Polyethylene Tubes, Films and Fittings with Measurement of Oduction Time (OIT) under Isotermic Conditions at 200 ° C in Oxygen, as according to UNI EN 728 and ISO 11357-6 standards.

Under the isothermal mode (OIT test), the materials are first heated in an inert atmosphere for N2, then kept at constant temperature for a few minutes until the thermal equilibrium is reached, and then purged with oxygen or air atmosphere. The time between the first contact with oxygen ( or air) and the onset of oxidation is called Oxidation Induction Time (OIT).

Thermal analyses

DSC thermal analysis for OIT (C.1-oit)

DSC thermal analysis for Tm, Tg and Tc determination (C.2-dsc)

With a TA differential scanner calorimeter. mod. 2000 heat fluxes are determined by heating or cooling the polymer material in a predetermined temperature range. Typically, the material is heated and brought to the melted state at a constant speed of 10° C / min (first fusion) and then cooled at the same rate in the same temperature range (crystallisation). In the second fusion, obtained under the same experimental conditions, the glass transition temperature (Tg), crystallization temperature (Tc) and melting temperature (Tm) are determined in a temperature range of -70 ° C to + 300 ° C.

The reference standards used for these measures are:

i) for Tg: ASTM D3418 and ISO 11357-2

ii) for Tm and Tc: ASTM D3418 and ISO 11357-3

Thermo-initiated polymerization kinetics (C.3-dsc)

Polymerization kinetics of thermal-curing polymers by DScC are carried out under isothermal conditions for the determination of Tg, crosslinking enthalpy, degree of cross-linking (α) and experimental conditions for post-curing.

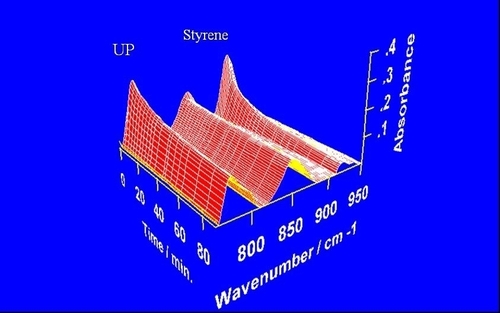

Photoinitiated polymerization kinetics (code C.4-dsc)

The DSC polymerisation of unsaturated polymers and acrylated monomers are determined by irradiation with visible UV light of the sample holder coupled with a fiber optic to a Hg lamp. Photocalorimetry allows to determine the Tg and the enthalpy of the photoinitiated polymerization reaction which is depending on the intensity of the incident radiation and curing temperature (20 ° and 60 ° C).

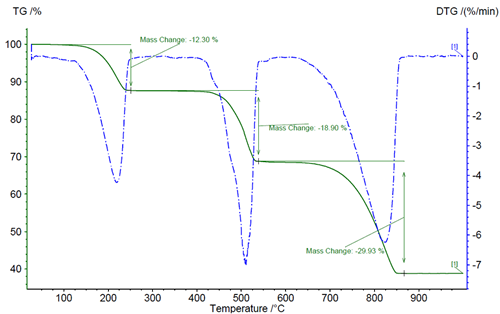

Thermogravimetric analysis - TGA (code C.5-tga)

The thermogravimetric (TGA) analysis of polymers is carried out with a controlled heating speed for the determination of the content by weight of volatile components (VOC, H2O) in a temperature range of between 30° and 200° C in presence of inert nitrogen flow gas of 50 ml / min and the content of mineral charges (ashes) and black smoke in air at T> 600 ° C.

Thermogravimetric (TGA) also allows to determine the thermal stability under pyrolysis and thermo-oxidation conditions by measuring the temperature of the weight loss (%) for heating (from 30 to 600 ° C) of plastics, composite materials, laminates, adhesives , foodstuffs, coatings, pharmaceuticals, organic compounds, elastomers and biological samples.

- The reference standard used is ISO 11358

- Determination of the content of black carbon black in PE pipes for drinking water transport is obtained in accordance with ISO 6964.